Description

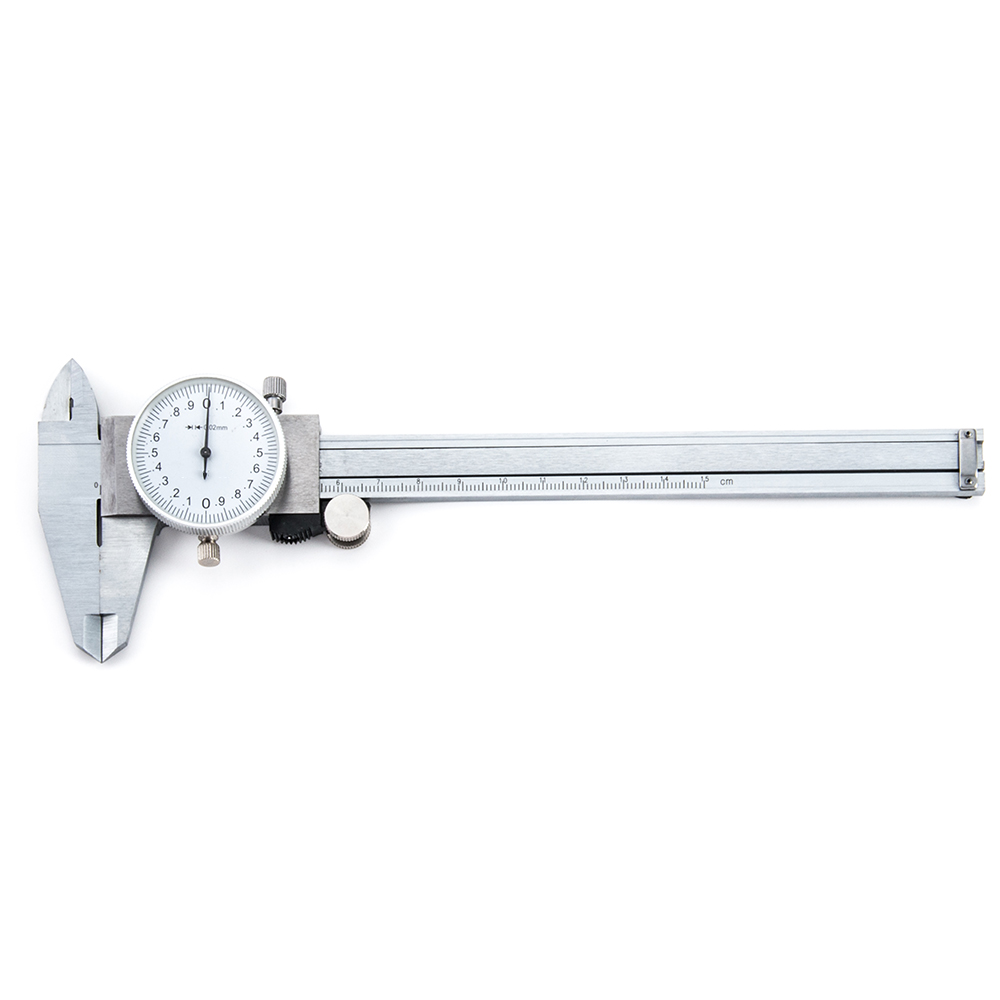

Material: made of high-quality alloy steel.

High precision dial with clear reading.

Specifications

|

Model No |

Size |

|

280060015 |

15cm |

Product Display

Operation method of capliers with dial:

Whether the use method of calipers with dial is correct directly affects the accuracy. The following requirements shall be observed during use:

1. Before use, the caliper with gauge shall be wiped clean, and then the ruler frame shall be pulled. The sliding along the ruler body shall be flexible and stable, and shall not be tight or loose or stuck. Fix the ruler frame with fastening screws and the reading shall not change.

2. Check the zero position. Gently push the ruler frame to make the measuring surfaces of the two measuring claws close. Check the contact of the two measuring surfaces. There shall be no obvious light leakage. The dial pointer points to "0". At the same time, check whether the ruler body and the ruler frame are aligned with the zero scale line.

3. During measurement, slowly push and pull the ruler frame by hand to make the measuring claw slightly contact with the surface of the measured part, and then gently shake the caliper with gauge to make it contact well. Since there is no force measuring mechanism when using the caliper with a meter, it should be mastered by the operator's hand feeling. It is not allowed to exert too much force to avoid affecting the measurement accuracy.

4. When measuring the overall dimension, first open the movable measuring claw of the caliper with the gauge so that the workpiece can be placed freely between the two measuring claws, then press the fixed measuring claw against the working surface, and move the ruler frame by hand to make the movable measuring claw closely adhere to the workpiece surface. Note: (1) the two end faces of the workpiece and the measuring claw shall not be inclined during measurement. (2) During measurement, the distance between the measuring claws shall not be less than the workpiece size to force the measuring claws to be clamped on the parts.

5. When measuring the inner diameter dimension, the measuring claws in the two cutting edges shall be separated and the distance shall be less than the measured dimension. After the measuring claws are placed in the measured hole, the measuring claws in the ruler frame shall be moved so that they are in close contact with the inner surface of the workpiece, that is, reading can be carried out on the caliper. Note: the measuring claw of vernier caliper shall be measured at the diameter positions of the holes at both ends of the workpiece, and shall not be sub inclined.

6. The measuring surface of the measuring claw of the calipers with gauges has various shapes. During measurement, it shall be correctly selected according to the shape of the measured parts. If the length and overall dimension are measured, the external measuring claw shall be selected for measurement; If the inner diameter is measured, the inner measuring claw shall be selected for measurement; If the depth is measured, the depth ruler shall be selected for measurement.

7. When reading, the calipers with meters should be held horizontally so that the line of sight is facing the surface of the scale line, and then carefully identify the indicated position according to the reading method to facilitate reading, so as to avoid reading error caused by incorrect line of sight.