Description

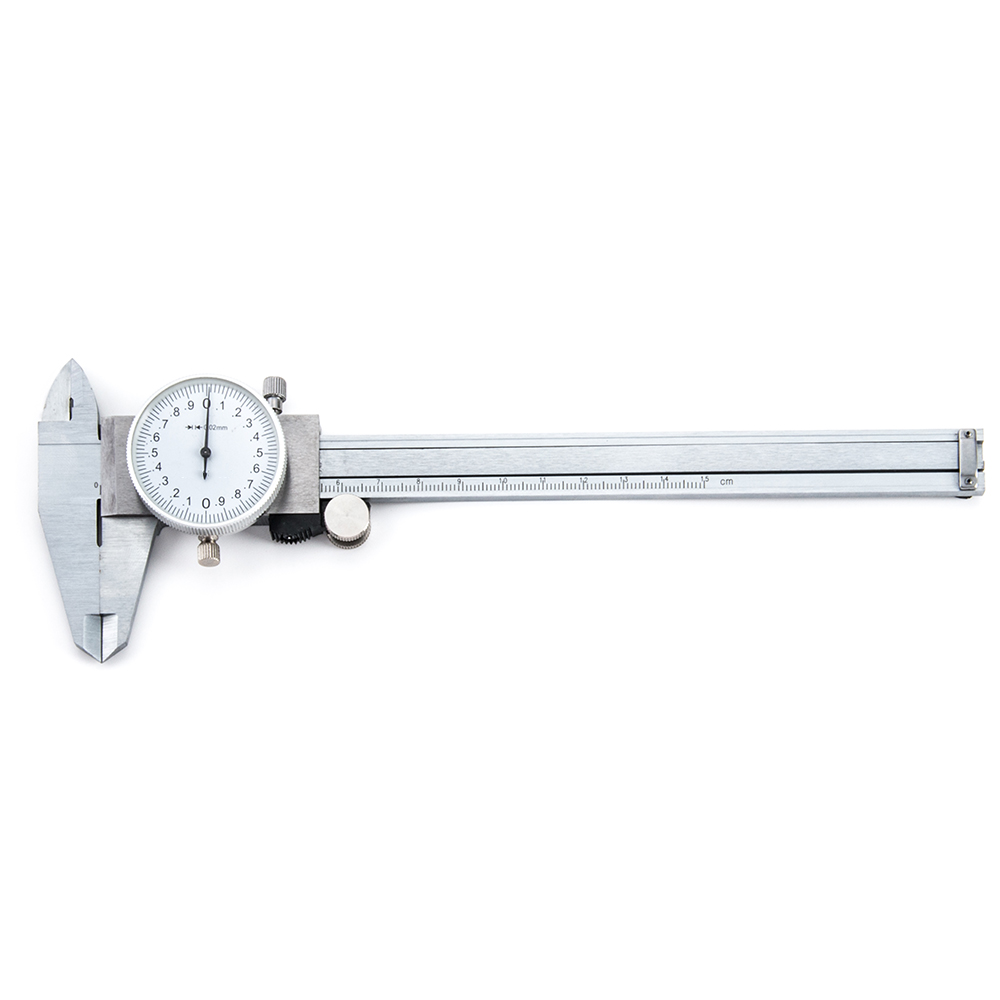

The vernier caliper is made of high-quality steel or stainless steel, which is carefully processed and manufactured after good heat treatment and surface treatment.

The metal caliper has the characteristics of high precision, long service life, corrosion resistance, convenient use and wide use.

Caliper is mainly used for measuring the internal hole and external dimension of the workpiece.

Specifications

|

Model No |

Size |

|

280070015 |

15cm |

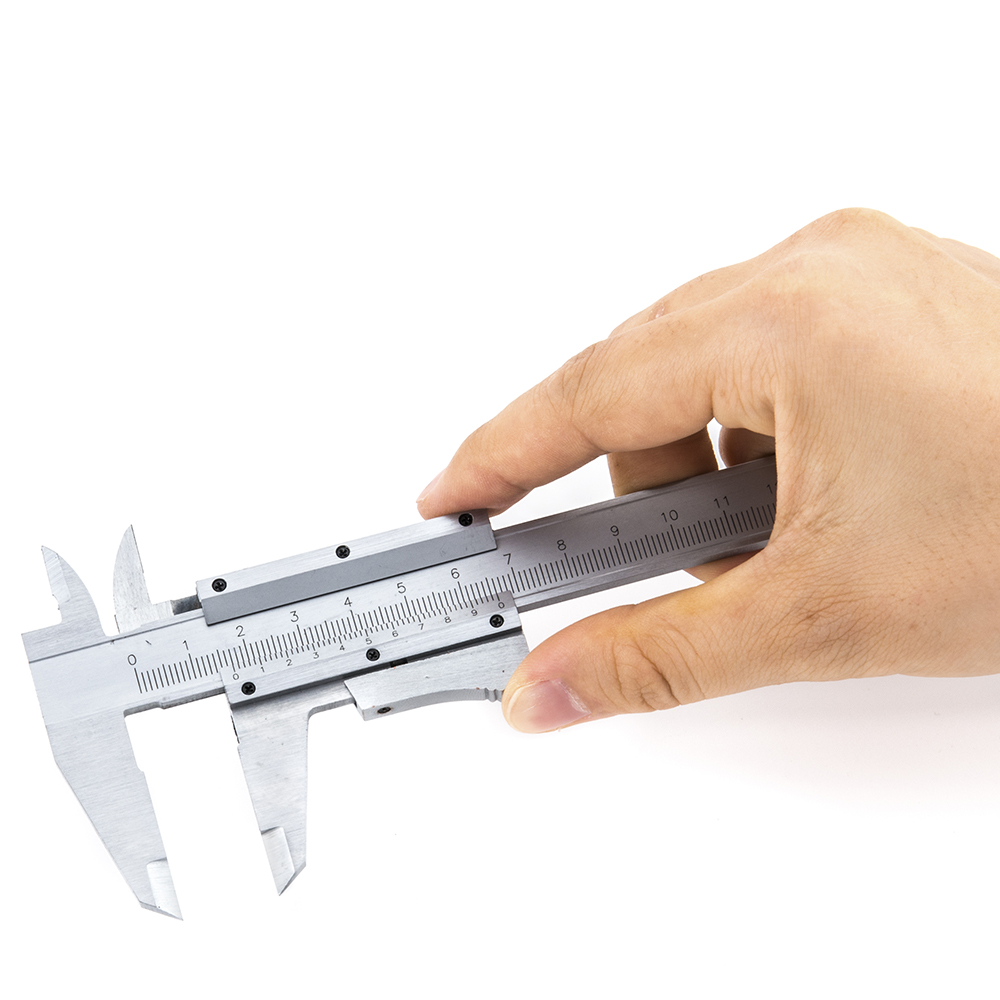

Product Display

Application of vernier caliper:

Vernier caliper is a relatively precise measuring tool, which can directly measure the inner diameter, outer diameter, width, length, depth and hole distance of the workpiece. Because vernier caliper is a kind of relatively precise measuring tool, it has been widely used in industrial length measurement.

Usage of vernier caliper:

1.When measuring the external dimension, the measuring claw shall be opened slightly larger than the measured dimension, then the fixed measuring claw shall be placed on the measured surface, and then the ruler frame shall be slowly pushed to make the movable measuring claw gently contact the measured surface, and the movable measuring claw shall be slightly moved to find out the minimum dimension position and obtain correct measurement results. The two measuring claws of the caliper shall be perpendicular to the measured surface. Similarly, after reading, the movable measuring claw shall be removed first, and then the caliper shall be removed from the measured part; Before the movable measuring claw is released, it is not allowed to pull down the caliper forcefully.

2.When measuring the diameter of the inner hole, first open the measuring claw slightly smaller than the measured size, then put the fixed measuring claw against the hole wall, and then slowly pull the ruler frame to make the movable measuring claw gently contact the hole wall along the diameter direction, and then move the measuring claw slightly on the hole wall to find the position with the largest size. Note: the measuring claw should be placed in the diameter direction o of the hole

3.When measuring the width of the groove, the operation method of the caliper is similar to that of the measuring aperture. The position of the measuring claw should also be aligned and perpendicular to the groove wall.

4.When measuring the depth, make the lower end face of the vernier caliper stick to the top surface of the measured part, and push the depth gauge downward to make it touch the measured bottom surface gently.

5.Measure the distance between the hole center and the measuring plane.

6.Measure the center distance between the two holes.