Description

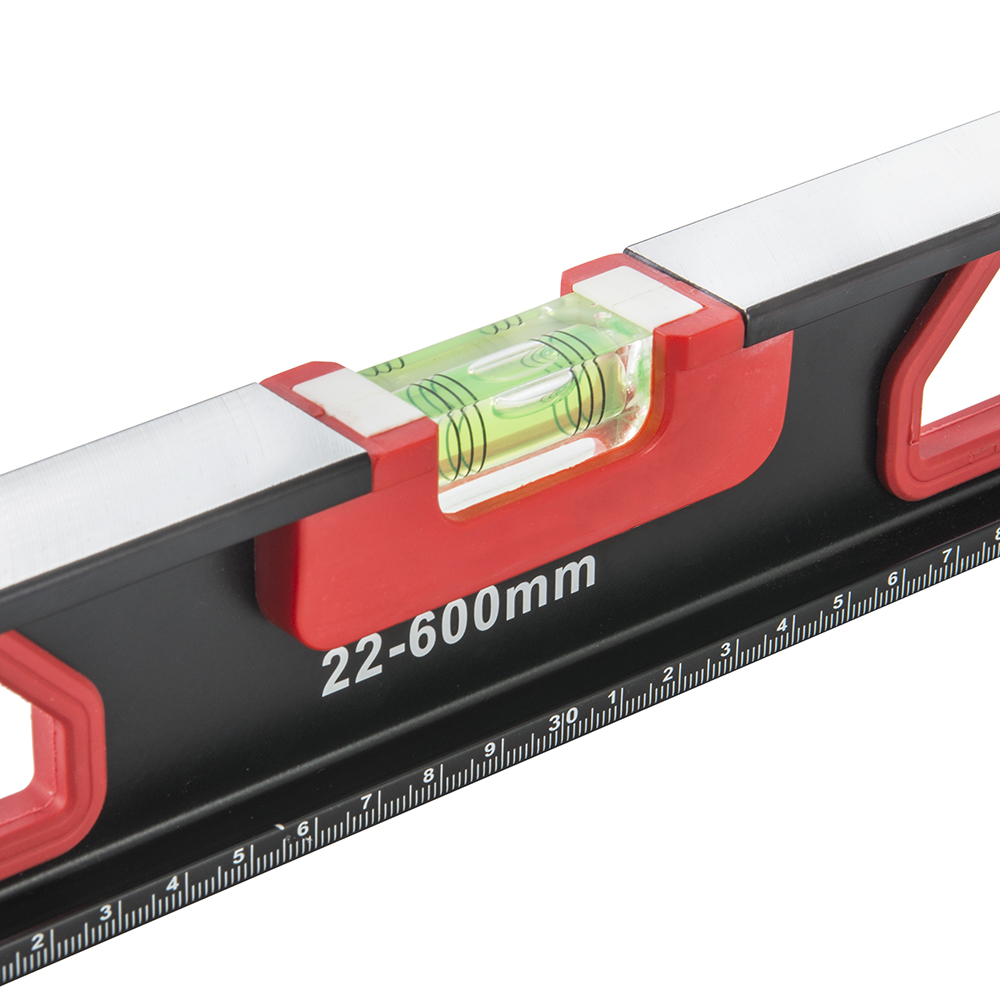

Heavy duty aluminum frame.

Electronic plated surface.

With three bubbles:two vertical bubbles and a horizonta bubble.

Inculde top and bottome milled working faces use both in normal position and when inverted.

Rubber end caps for anti shock when dropping.

Specifications

| Model No | Size | |

| 280110024 | 24inch | 600mm |

| 280110032 | 32inch | 800mm |

| 280110040 | 40inch | 1000mm |

| 280110048 | 48inch | 1200mm |

| 280110056 | 56inch | 1500mm |

| 280110064 | 64inch | 2000mm |

Application of spirit level

The spirit level refers to a common measuring tool for measuring small angles. In the mechanical industry and instrument manufacturing, it is used to measure the inclination angle relative to the horizontal position, the flatness and straightness of the guide rail of machine tools, the horizontal and vertical positions of equipment installation, etc.

Product Display

Tips:precaution of using spirit level

The spirit level is an angle measuring instrument for measuring the inclination angle deviating from the horizontal plane. The internal surface of the main bubble tube, the key part of the level, is polished, the external surface of the bubble tube is engraved with a scale, and the inside is filled with liquid and bubbles. The main bubble tube is equipped with a bubble chamber to adjust the bubble length. The bubble tube is always horizontal to the bottom surface, but it is likely to change during use.

1.Before measurement, the measuring surface shall be carefully cleaned and wiped dry, and the measuring surface shall be checked for scratches, rust, burrs and other defects.

2.Check whether the zero position is correct. If it is not correct, the adjustable level should be adjusted as follows: place the level on the flat and read the scale of the bubble tube. At this time, at the same position on the flat plane, turn the level 180 ° from left to right, and then read the scale of the bubble tube. If the readings are the same, the bottom surface of the level gauge is parallel to the bubble tube. If the readings are inconsistent, use a spare adjusting needle to insert into the adjusting hole for up and down adjustment.

3.During the measurement, the influence of temperature shall be avoided as much as possible. The liquid in the level has a great influence on the temperature. Therefore, the influence of hand heat, direct sunlight, Kazakhstan and other factors on the level shall be noted.

4. In use, readings shall be taken at the position of the vertical level to reduce the influence of parallax on the measurement results.